Master Lean Six Sigma Green Belt – International Online Certification Program

100% Online: join from anywhere!

Designed for international teams

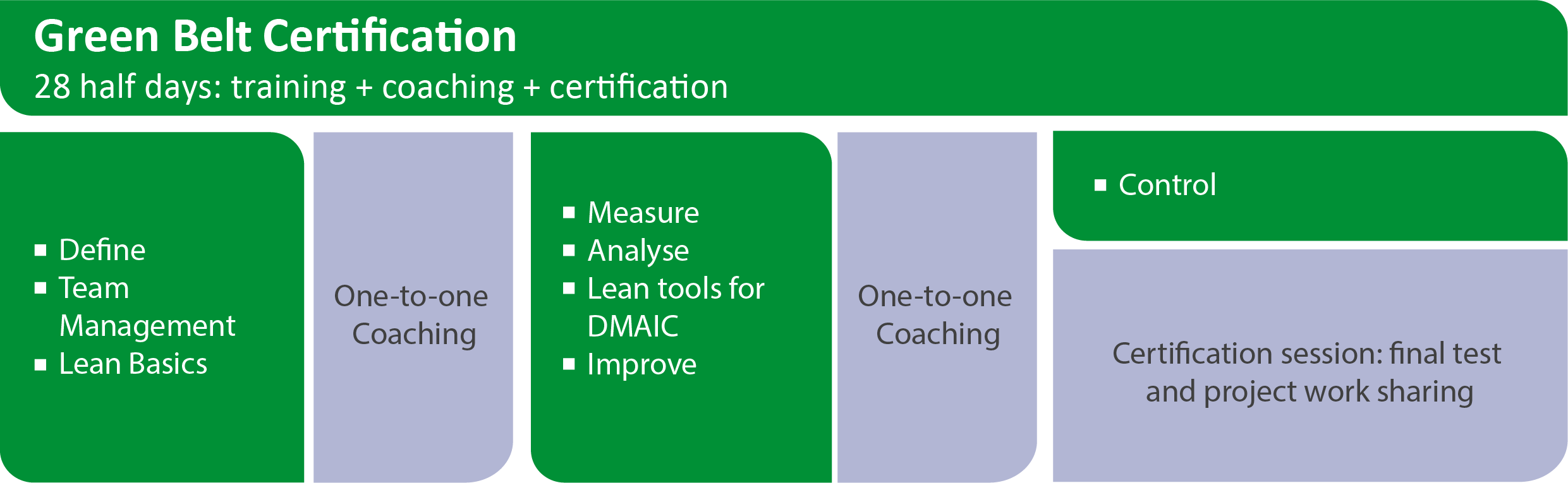

- 28 live webinars (4h each) – full training in English

- A best-of-breed, hands-on program chosen by Philip Morris International, Pirelli, Barilla, Lavazza, Lynxeo, Cogne Acciai Speciali and many more

- Ideal for Industrial and Service processes. Practical tools to improve real operations

- DMAIC-based project work deliver real business savings

- 1:1 tutoring with certified Master Black Belts

- Practical exercises, Minitab™, team coaching and case studies

- Final exam & certification aligned with ISO 13053 and ISO 18404

- All sessions are recorded: don’t miss a thing!

- Lean knowledge add-on via our digital learning platform LX

- Pre-course online assessment & review tests

The Map

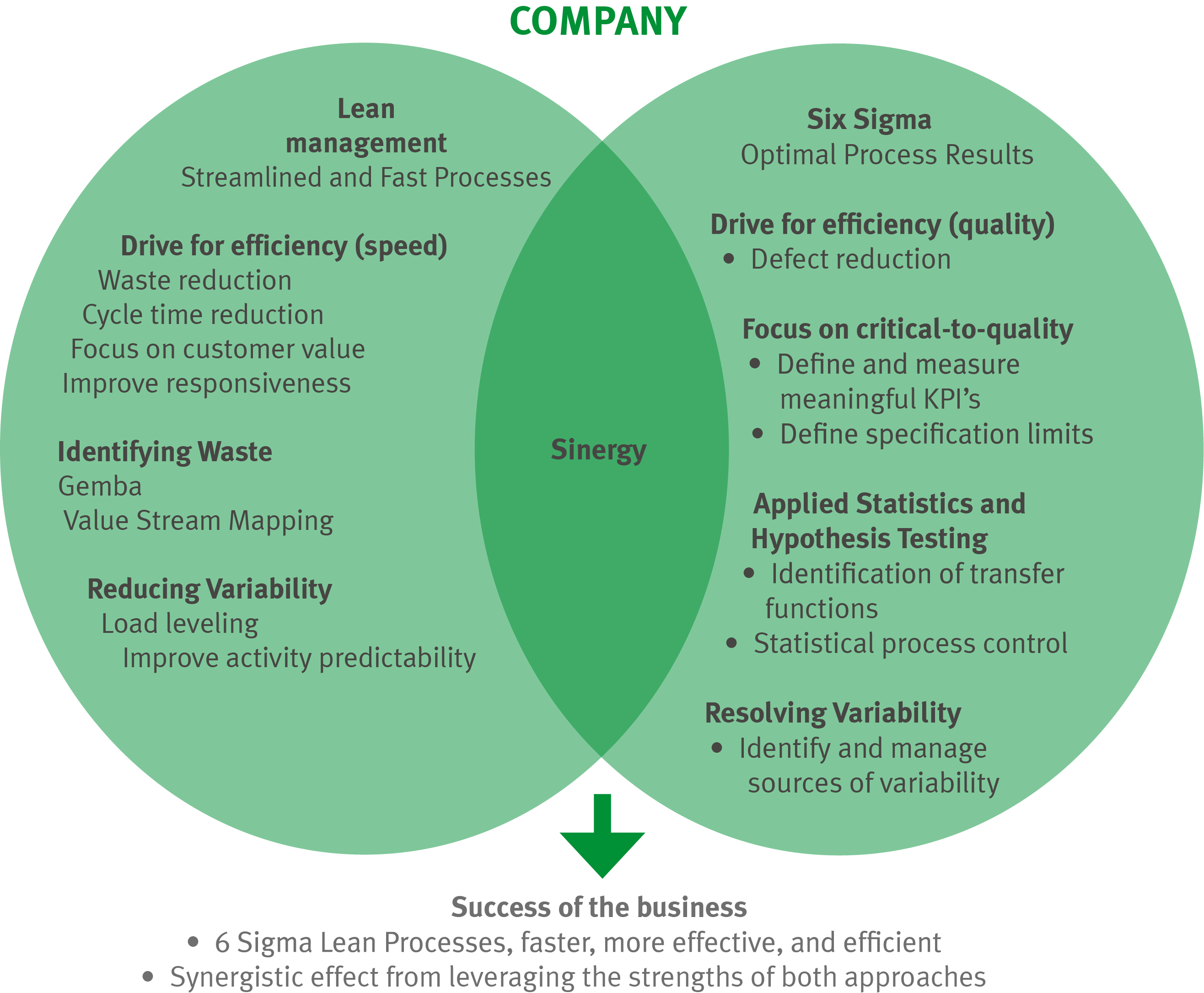

Lean Six Sigma

Lean provides efficiency and flexibility in production and decision-making processes, reducing waste.

Six Sigma improves the reliability and quality of internal processes, products and services offered to customers.

Together:

- Enable optimization of the choice of analysis and intervention tools according to the complexity of problems and expected costs/benefits

- Give stability and solidity to processes of improvement and change throughout the organization

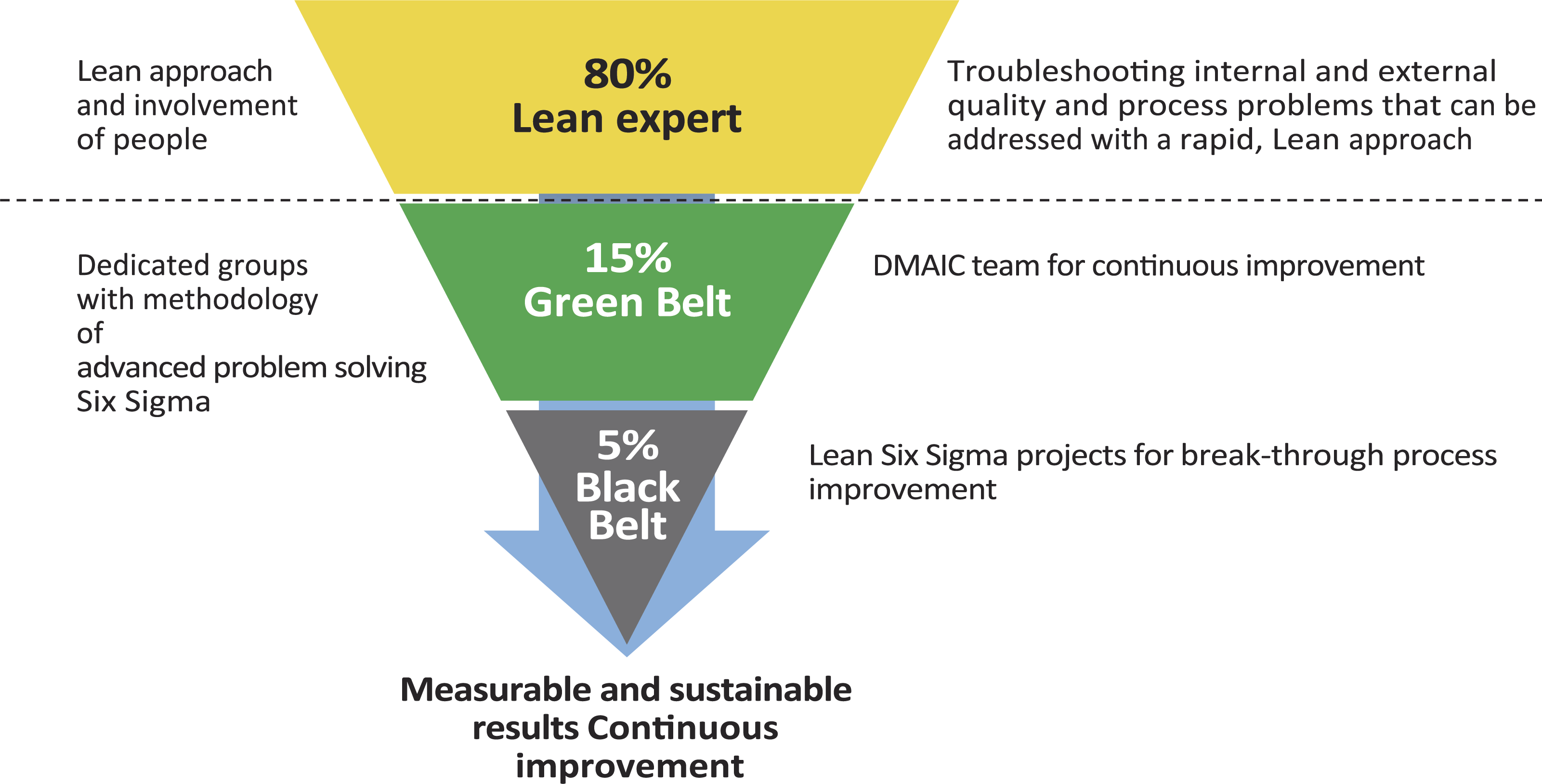

Hierarchy of problem solving and escalation

Six Sigma

Six Sigma method is an improvement strategy that relies on the power of objective measurement.

It combines tools and techniques used in Total Quality Management to analyze the root causes of problems in business processes and aims to reduce errors and control results to a 6 Sigma level (3, 4 errors per million opportunities).

- An approach and mindset that provide a rigorous methodology for improvement and project management

- A structured set of methodologies to achieve high quality levels

- An analysis methodology that integrates analysis of available data, processes, and information to identify causes of problems

- A process improvement program geared toward customer satisfaction and reduction of non-quality costs

- A methodology that can be applied to all business areas, thus to both the logistics-production area and the commercial-administrative area

Six Sigma is successfully used in companies of different sizes with some specificities depending on the context.

It can also be used on individual issues by involving “technical” task forces, but the most significant results are achieved with the extended in-house approach.

Lean

The guiding principle of Lean leads the company to focus resources on creating the value required by the customer through radical simplification of processes, stimulating an active contribution of people and promoting an integrated use of technology and human activities. Lean has proven its effectiveness in both industrial and service processes by enabling great results in terms of effectiveness and efficiency with simple and shared tools, leveraging the value of people and the contribution to improvement that those working in the process can make.

The model is based on the concept of value, analyzing what the “customer’s perceived value” is, that is, what the customer is willing to pay the asking price for.

8 Muda

Learning to see what is not visible and recognize sources of waste

Integrating Lean and Six Sigma

A Six Sigma program will be most effective if it deals with lean and simple processes.

A Lean program will be more effective if it deals with processes that are governed and not subject to variability.

Benefits for the company

Increase productivity and profitability through:

- Increased value-added activities and reduced waste and defects

- Reduction of non-quality plant costs, from production costs to warehousing and transportation costs

- Increased production efficiency

- Reducing transactional costs of non-quality

- Reducing process variability

- Increased customer satisfaction

Orient the corporate culture toward improvement with rigor and rationality through:

- Trained and improvement-oriented staff capable of leading internal dissemination of the approach

- Focus on quality and real customer needs

- Application of structured problem solving methodologies

Proper implementation of the Six Sigma methodology enables economic benefits that can be estimated in the range of 2 to 3 percent of turnover, with peaks of 10 percent.

Festo Group uses the Lean Six Sigma approach in both industrial and transactional areas including projects, for example, in Marketing and Sales areas.

Potrebbe interessarvi anche

Argomenti correlati

S

h

a

r

e